|

Hide Changes |

|

|

|

Recent Changes |

|

Subscriptions |

|

Lost and Found |

|

Find References |

|

Rename |

| Search |

History

| 4/14/2018 4:17:36 AM |

| 91.248.34.151 |

| 12/21/2015 4:50:41 PM |

| 209.142.130.225 |

| 8/16/2012 9:34:10 AM |

| -86.141.128.90 |

| 7/14/2012 2:59:37 PM |

| 217.129.153.96 |

| 6/27/2012 6:00:08 PM |

| -86.132.180.77 |

|

List all versions |

| Link to Wiki HomePage | Link to the main site: http://www.fordsontractorpages.nl | Link to the forum: http://www.fordsontractorpages.nl/phpbb3 |

Super Major, Dexta and Super Dexta Hydraulic Lift Settings.

There are two types of lift fitted on the Super Major, Dexta, and Super Dexta tractors. The first type is the single acting lift fitted to all Super Major tractors up to 1963 and Dexta and Super Dexta tractors throughout the life of the marquee. The second is the double acting lift fitted to New Performance Super Major tractors after 1963.

The wording single and double acting refers to the operation of the draft control linkage rather than the output of the hydraulics.

On all top link-sensing tractors, in draft control (Qualitrol), pressure on the top link is used to measure the load being applied to the tractor by the implement.

When an implement, mounted on the third point linkage is working in the ground, a force (draft) is trying to rotate the implement around the lower link connection. This causes a pressure or tension on the top link that is transmitted to the control valve through a series of external and internal springs.

The main control lever is not connected directly to the control valve but is so arranged that it can change the spring force required to move the control valve from the external linkage or override this linkage and cause the control valve to move into the raise position.

As the lift reaches the fully raised position, the piston protrudes clear of the ram cylinder bore and contacts on a pin fixed in the linkage that causes the control valve to move to the neutral position.

When the lift is lowered, the lever moves in such a way as to remove all spring pressure from the control valve linkage and allows the spring mounted on the front of the control valve to push the valve into the lowering position.

In operation, the load (draft) is set by the position of the main control lever in its quadrant. The nearer the top of the quadrant the less pressure is required on the top link, for the lift to raise. As the lever is moved down the quadrant a greater pressure is required before the lift raises.

If a tractor and implement is working in light soil the lift control lever may have to be close to the top of the quadrant to hold the implement at the required depth in the soil. This is because the draft forces in light soil are low and the lift needs to be sensitive to small changes in the force.

In heavy soil the lift lever will have to be further down the quadrant for the implement to retain the same working depth as above. This is because the heavier soil imposes greater draft forces on the top link.

These corrections can be further controlled by a flow control valve fitted to some tractors, which adjust the flow of oil to the ram cylinder, and causes the lift to raise more slowly when in work. This avoids the implement being lifted completely out of work but allows it to lift enough to reduce the load on the tractor.

Draft control also allows the wheel slip on the tractor to be controlled. As the tractor’s wheels start to slip soil is removed from beneath them by the tyre treads causing the rear of the tractor to sink. As the rear sinks, pressure is increased on the top link by the sinking as the tractor changes its position in relation to the implement.

The lift senses the increase in pressure and raises the implement causing the weight of the implement plus draft to be applied to the rear wheels. This action reduces wheel slip and the tractor moves on.

If wheel slip is a problem weight can be added to the tractor to overcome this. On tractors operating three-point linkage equipment, this weight should be added to the front of the tractor to stop the front from lifting, and to the implement so that tractor and implement pivot on the rear wheels. Weight added directly to the rear wheels is dead weight and is only of use when dragging implements from the drawbar.

Draft control (Qualitrol) is NOT a depth control system. It is a LOAD control system controlling the load placed on the tractor by an implement within the parameters set by the operator, by the position of the control lever.

On the early Super Major, Dexta and Super Dexta tractor the hydraulic lift, in draft control, responds to pressure on the top link. This causes the implement to raise. Once the pressure on the top link is released, the implement is lowered.

On the New Performance Super Major pressure on the top link causes the lift to raise and when the pressure is reduced the lift will lower. But with longer or heavier implements working in light soils compressive force on the top link may not be generated. The lift is designed to work with both pressure and tension forces acting on the top link hence the double acting designation. As the tension of a long implement pulls the top link beyond a set point, the lift will raise.

Setting of the lift differs between the 1960 to 1963 Super Major and the 1963 to 1964 New Performance Super Major.

Draft Control Setting 1958 to 1964 Dexta and Super Dexta. 1960 to 1963 Super Major.

Draft Control Main Spring.

Select draft control.

Lower the lift arms and set lever at bottom of the quadrant.

Remove pin that connects top link yoke to spring link.

Turn spring link on thread until all movement is taken out between spring and spring link and spring pressure is felt.

Re-connect top link yoke.

New Performance Super Major 1963 to 1964.

Draft Control Main Spring.

As above

Turn spring link until all movement is taken out of spring then tighten until movement returns.

Back off to position of minimum/no movement.

Re-connect top link yoke.

Pressure Test.

The simple way to pressure test is to connect the pressure gauge into the external services port. A pressure gauge reading at least 4000 psi (285 kg/sq.cm) will be required.

Connect gauge.

Set engine revs at 1600 rpm

Run tractor until oil is hot. (Deadheading the auxiliary service output for a short period can do this).

Lower lift arms about1/2” (13mm).

Pull out auxiliary service knob.

Read pressure gauge. Pressure should read 2450 to 2550 psi (172.24 to 175.77 kg/sq .cm). These are the figures for a new pump. 2250 to 2500 psi (160.71 to 178.5 kg/sq.cm) is within limits for an older tractor. Do not allow pressure to exceed 2550 psi (175.77 kg/sq.cm).

To set the pressure shims are fitted or removed from beneath the spring in the pressure relief valve. Remove the valve from the hydraulic pump, on the Dexta / Super Dexta, or from the front of the lift housing near the auxiliary service knob on the Super Major. Remove the sealing “O” ring and grip the end of the valve in a soft jawed vice. Unscrew the end and remove. In the end cap is the valve seat and the valve plunger, check for damage on the seat and on the valve. The seat will be clearly seen.

Remove the spring from the housing. If no shims come out with the spring, sharply tap the hollow end of the housing on a piece of wood or soft surface so as not to damage it. Any shims should fall out. These shims are .010” (0.254 mm) and .025” (0.635mm) thick. Shims of these thicknesses can be added to increase the system pressure but should be used with caution and in conjunction with a pressure gauge as damage to the hydraulic system and to the operator could occur if the pressure is set too high.

If the pressure does not increase after shims have been added, the fault is not in the pressure relief valve and any extra shims fitted should be removed before the problem is rectified.

Super Major (up to 1963) and Dexta / Super Dexta lift settings.

The hydraulic lift is very heavy and awkward. Proper lifting equipment should be used to lift this from the tractor.

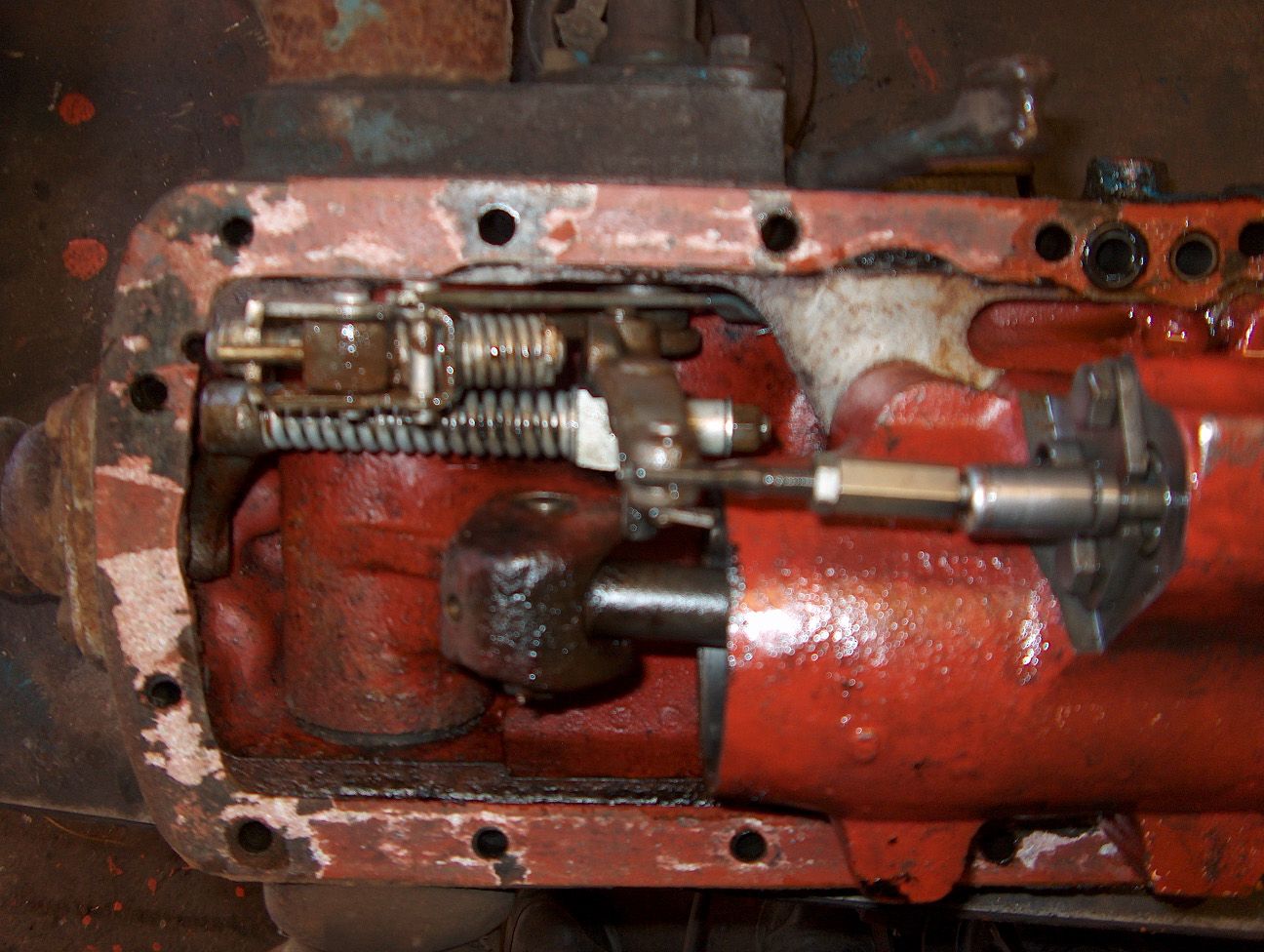

Remove hydraulic lift from the tractor and place on workbench with ram cylinder upwards. A trumpet shaped guide is fitted to the control valve on the Super Major and a metal tube on the Dexta. Check that this is undamaged. Any damage may indicate that this area has been hit or bent by the lift being dropped or laid on the valve and this may cause sticking problems.

Qualitrol (Draft) Control adjustment. This must be done before Position Control Adjustment.

Move the lift arms to the fully up position. (As the lift is on its back this will mean that the arms are fully down). Now move the arms down until the upper surface of the yoke in which the linkage fits is level with the gasket surface of the lift housing. This can be checked with a straight edge. The arms can be held in this position by tightening the arm retaining studs. Do not forget to slacken these when the lift is replaced.

Set the draft/position control selector into “Qualitrol” (draft).

Set the main lift control lever to the upper raise stop in the quadrant then move it towards the lower position until the upper edge of the lever is 13mm (1/2”) from the top stop.

Adjust the turnbuckle on the control valve until the front edge of the control valve is 10mm from the rear face of the control valve bush in the ram cylinder.

Tighten the turnbuckle lock nut and recheck the measurement.

Position Control Adjustment.

Lift arms in the same position as with the Qualitrol adjustment.

Set the draft/position control selector to Position Control.

Set the main control lever to the lower stop at the bottom of the quadrant.

Identify the position control rod. This will be pushing on a flat area on the control valve operating lever.

Slacken the locknut on the position control rod and turn the rod until a measurement of 13mm is found between the front edge of the control valve and the rear face of the control valve bush.

Tighten position control rod locknut.

Refit lift with new gaskets and “O” rings and having care not to rest the lift on the control valve when refitting it.

Slacken off lift arm retaining studs until arms move freely then refit lock tab.

New Performance Super Major with Double Acting Lift.

Draft Control Adjustment.

Setting of lift arms as for single acting lift.

Select Draft control.

With main control lever at bottom of quadrant, place a 10mm gauge between the control valve and the face of the ram cylinder.

Bring control lever to within ½” (13mm) of top quadrant stop trapping the gauge firmly between the valve land and the ram cylinder. A strong spring pressure will be felt as this is done and the spring on the rod between the top link linkage and the control valve arm will be seen to compress as the connecting fork slides along the shaft. A measurement of 0.200” should be measured between the circlip and the actuating fork should be obtained. This can be adjusted by the turnbuckle at the control valve.

Position Control Adjustment.

Lift arms in the same position as with the Qualitrol adjustment.

Set the draft/position control selector to Position Control.

Set the main control lever to the lower stop at the bottom of the quadrant.

Identify the position control rod. This will be pushing on a flat area on the control valve operating lever.

Slacken the locknut on the position control rod and turn the rod until a measurement of 13mm is found between the front edge of the control valve and the rear face of the control valve bush.

Tighten position control rod locknut.

Refit lift with new gaskets and “O” rings and having care not to rest the lift on the control valve when refitting it.

Slacken off lift arm retaining studs until arms move freely then refit lock tab.

Problems with getting the correct control valve setting. Dexta and Super Major

Basic setting.

Lift arms parallel to the lift top cover

Draft control selected.

Draft control spring adjustment correct. Just able to turn the spring by hand and no free movement on a Dexta and no free play on a Super Major.

Control lever ½” (13mm) from top stop.

Control valve should be:

½” (13mm) between land on valve and rear face of ram cylinder.

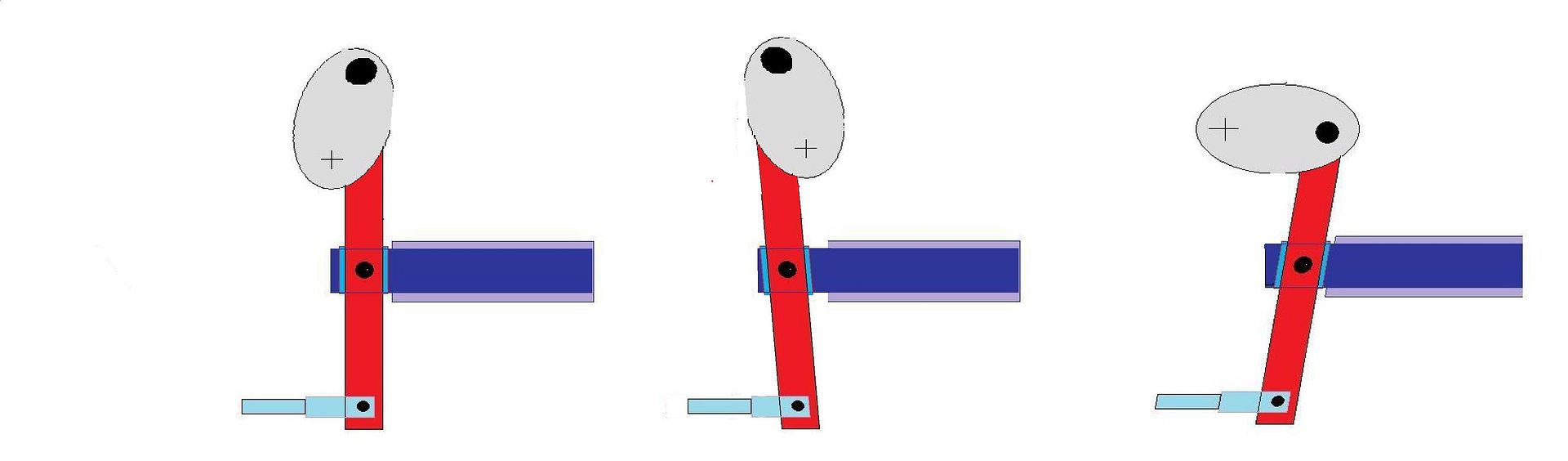

Valve control linkage in neutral. ----- Lowering ------------------------- Raising.

When the lift lever is moved up the quadrant the offset pin on the end of the quadrant lever shaft moves the valve control linkage towards the back of the lift housing. There is no direct connection to the control valve, the system works by balancing springs in the linkage.

The linkage has a pivoted bush or fork through which the link from the top link moves. A strong spring on the shaft presses against this bush and prevents the valve control linkage from moving back, this causes the valve control arm to tilt and move the control valve to the raise position.

Alternatively, with the quadrant lever at a position above halfway up the quadrant, pressure on the top link will move the linkage through the bush, compressing the spring slightly and moving the control valve to raise.

If the main draft control spring on the rear of the lift is not correctly adjusted before attempting to set the lift, or the linkage seized and not moving or damaged this will affect the position of the valve control linkage and the position of the control valve for initial setting and the measurement required will not be achieved.

Wear or a bent pin on the quadrant lever shaft can also cause the same problem.

Bent lever shaft.

Sheared lever key.

Common Problems.

Lift Dropping or over correcting.

Test:

Raise lift fully.

Pull out Auxiliary Service Chest Knob.

If lift stops dropping:

Leak on Control Valve.

Leak on Unload Valve Plug.

Leak on Check Valve.

If lift continues to drop:

Leak on Piston Seal.

Leak on Ram Cylinder "O" Rings.

Leak on Auxiliary Service Chest "O" Rings.

Faulty Ram Cylinder Safety Valve.

Lift will not lift load/lifts slowly.

Faulty Pump "O" rings.

Faulty Pressure pipe "O" Rings.

Faulty Pressure Relief Valve.

Worn Pump.

Stuck Flow Control Valve in Auxiliary Service Chest.

Lift settings need Adjusting. Try pushing the Draft/Position selector further towards the rear of the tractor. (Dexta/Super Dexta). If lift raises/increases in lift speed then linkage is out of adjustment and the Position Control pin is worn.

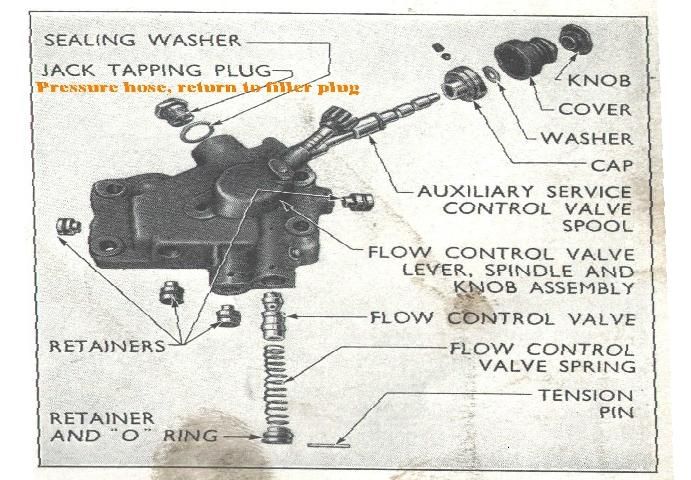

Auxiliary Service Chest contains the divert valve for providing oil for trailers, loaders and other equipment. Implements can be controlled by the main control lever or a constant flow of oil can be obtained by taking the main control lever beyond the top stop on the quadrant. This causes the control valve to by-pass the "knock off" pin which contacts the piston when the lift is fully raised moving the control valve into neutral. The constant flow can be used to drive hydraulic motors and the Flow Control used to regulate speed of the motor, or provide an oil flow for "add on" valve blocks used to control implements. In these cases return oil should be piped back into the rear axle via the filler cap which should be modified.

The Auxiliary Service Chest also contains the Flow Control Valve which is used to regulate lift corrections when using implements such as ploughs and cultivators in draft control. The flow control function can also be used as above. Adjustment is made by the screw adjuster.

When in use "Flow Control" slows the rate of lift, to avoid delay in raising an implement, a linkage and an extension wheel on the lift lever can be activated to move the flow control into the "Maximum Flow" position as the lever is moved up the quadrant.

Lift Raises with Control Lever in Lower Position.

Position Control selected when using Auxiliary Service Port.

Stuck Unload Valve.

DO NOT DRIVE OUT WITH PUNCH. Punch is only for indication. Remove Unload Valve Plug with puller/slide hammer and GENTLY tap valve out. Clean valve with metal polish NOT wet and dry or emery paper. The correct "O" ring must be used if being replaced, this is a CNH part and should be obtained from a Case-New Holland Dealer. It is made from a special rubber compound. Alternately the "O" Ring can be left off or a later style valve with a metal piston ring fitted.

| Link to Wiki HomePage | Link to the main site: http://www.fordsontractorpages.nl | Link to the forum: http://www.fordsontractorpages.nl/phpbb3 |

If you are new to Wiki, read OneMinuteWiki or VisitorWelcome.

Recent Topics